Discussions on radiation and space environment exposure of replicated optical mirrors produced from carbon composites

R. C. Romeo*a, R. N Martina, K. Bollwegb

aComposite Mirror Applications, Inc., 1638 S. Research Loop, Tucson, AZ, USA 85710-6769

bNASA Johnson Space Flight Center

ABSTRACT

Radiation effects are well known to cause significant degradation in polymer materials. Low earth orbit (LEO) radiation exposures cause ionization potentials that can undermine mechanical properties of polymers. In particular, small scale degradations can undermine carbon / polymer composite mirrors used in imaging applications. A high-specularity surface finish is required for optical mirrors and that surface is vulnerable to radiation ionization degradation thereby undermining the optical performance of the mirror in that environment. Experiments involving radiation ionization and its effects on replicated carbon/polymer composite mirrors will be discussed; 6 replicated carbon/polymer composite mirrors on the Materials on the International Space Station Experiment, MISSE 7A and MISSE 8, the replicated RICH mirror the Alpha Magnetic Spectrometer (AMS-02) and testing on the RICH 1 replicated mirrors in the LHCb experiment. Results are favorable for optically coated composite mirrors in terms of mirror figure, reflectivity and surface finish, but not so on uncoated polymer mirrors.

Keywords: composite mirrors, RICH mirrors, space qualified optics, carbon fiber composites, MISSE, AMS-02

1. INTRODUCTION

Four major programs involving replicated continuous fiber reinforced polymer (CFRP) mirrors are presented here. Since the late 1980’s the author has been involved in developing techniques for producing diffraction-limited (vis.) mirrors via replication processes. Replication promises to significantly reduce time, weight and cost associated with producing high quality optical mirrors. The centerpiece of the replication process is the establishment of a mold for the optic referred to as a mandrel. The mandrel is typically a glass or ceramic material, which is polished and figured to the desired final optical tolerances but in the negative curvature. Figure 1 below show the basic process steps of replicated CFRP mirrors.

Figure 1 basic steps in the replication of CFRP mirrors

For this discussion, we will address replicated CFRP mirrors produced from carbon fiber reinforcement in the composite. Carbon fiber composites have many redeeming features making them ideal for space flight and high energy physics applications. As a result, we have 4 programs from which radiation exposure and/or low earth orbit exposure data is discussed.

*RobertRomeo@compositemirrors.com; phone 1 520 733-9302; fax 1 520 733-9306; compositemirrors.com

2. MISSE 7A & MISSE 8 MIRRORS

CMA mirrors operating in a LEO environment must be able to survive the monatomic oxygen and UV exposure. Between 2009 and 2013, CFRP mirrors were produced at CMA for the both MISSE 7A & 8 experiments under invitation and direction of The Aerospace Corp. and the Naval Research Laboratory. The goal of this experiment was to determine the effects of a LEO environment on CMA’s lightweight mirror technology and how they may impact their use in space-based imaging telescopes. MISSE 7A was flown on STS-129 in 2009 and MISSE 8 was flown by STS 134 in 2011, the same mission retrieving MISSE7A samples. Table 1 below defines the specifics of the exposures of the MISSE samples on the ISS.

Table 1 Details of the exposure of both MISSE 7A and MISSE 8 samples.

2.1 MISSE 7A

In 2008, MISSE 7A samples were produced using state-of-the-art materials; high modulus fibers, pitch- based with cyanate ester resin as the binding material or matrix. The materials were chosen to meet optical performance as well as meeting ASTM-595 specifications for low outgassing, low condensable volatile materials and low moisture uptake. Two flat CFRP mirrors and one spherical mirror were produced as shown in figure 1. The mirrors were positioned at nadir [1] (earth center) for a total of 1.49 years before being retrieved. The spherical mirror and a one of the flat mirrors were coated with aluminum and SiO. Optics in typical imaging systems have protection

Figure 2 Left image shows the MISSE 7A tray on the ISS, Right image shows the CFRP mirrors preflight

from an enclosure and cover system as well as some sort thermal management. This means the MISSE 7A environment is considered a relatively severe environment case for most coated optics.

The resulting figure change in the mirrors is shown in figure 3. Interferometric images were possible Postflight which indicates that the resulting figure distortions were not so severe as to preclude the measurements [2]. Further investigation of the surface degradation shows crazing of the coated mirror, indicative of large temperature swings from ~17,400 day-night cycles as shown in figure 4. The uncoated flat mirror displays local degradation and overall erosion of the surface. Measurements were made of the erosion of the uncoated flat mirror’s exposed area andcompared to the area at the edge from the mounting of the sample where it was somewhat protected from the elements.

Figure 3 Pre and post-flight interferograms of the MISSE 7A samples

Results indicate a nearly uniform erosion of ~350nm as shown in figure 5. Interestingly, the surface was still smooth enough to obtain interferometric fringes, indicating small degradation in surface finish. The uncoated mirror also showed signs of small-scale erosion or pitting, which is to be expected with an unprotected epoxy resin surface.

Figure 4 Left shows a 20X image of the crazed optical coating from the coated flat, right shows the pitting caused by the AO exposure of the uncoated mirror. Inset shows the preflight surface quality of the uncoated mirror surface as a reference.

Figure 5 3-D map and profile measurements showing a ~350 nm erosion of the polymer surface but relatively uniform. The interferogram indicates a specular surface.

2.2 MISSE 8

Mirrors produced for MISSE 8 were only recently returned to earth so a thorough analysis has yet to be completed. However, some AO degradation was obvious on the uncoated sample and micrometeorite events on one of the coated samples is yielding interesting data. The MISSE 8 mirrors were installed on the Optical Reflector Materials Tray (ORMatE-III) [3] in the ram direction. This environment is much more severe that the MISSE 7A samples experienced pointing at nadir. In addition, MISSE 8 samples were kept outside the ISS for 2 years.

The MISSE 8 CFRP mirrors were upgraded somewhat over the MISSE 7 samples but were not optimized based on the MISSE 7A results because of the lag time between the experiments. CMA simply applied the latest techniques to the

fabrication and added a slightly different matrix in the composite than the previous samples. Figure 6 shows the preflight MISSE 8 mirrors at CMA before shipment to the NRL and the ORMatE-E-III flight tray in-place on the ISS.

Figure 6 Left shows MISSE 8 samples before shipment to NRL, Right ORMatE-III tray installed outside the ISS.

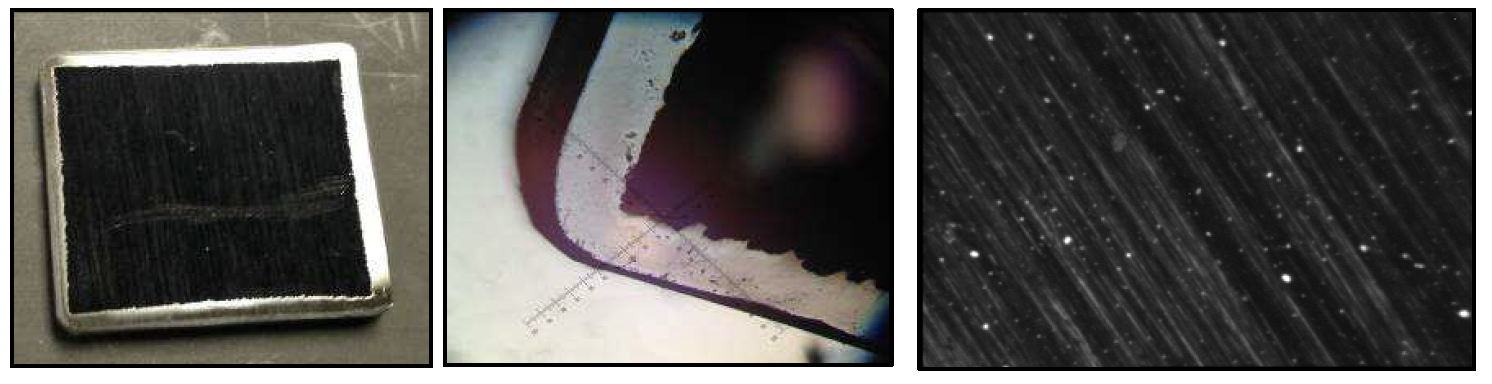

A thorough investigation has not been completed but there were certain obvious signs of degradation in the mirrors that should be noted. Firstly, the uncoated flat exhibited a complete erosion of the front polymer surface, which was initially 75 microns thick. In addition, there is no sign of resin matrix that accompanies the CFRP composite. The front surface was a 2-part epoxy system used in the replication and the matrix was a cyanate ester resin system. The AO erosion of the polymer occurred in the exposed area of the mirror and seems to have begun eroding the perimeter of the mirror under the square mounting frame outlining the flight tray. This is clearly shown in the non-uniformity of the perimeter due to undercutting of the polymer in the left and center images of figure 7 below.

Figure 7 Uncoated flat sample clearly indication complete erosion of the replicated optical surface, shown also is residual optical surface resin at the perimeter of the mirror that was protected by the mounting frame.

A feature most notable on the spherical samples is the micrometeorite impact. The impact affected the optical epoxy surface and coating to a size of roughly 2 mm in diameter. The actual impact damage is ~750 micron diameter hole in the laminate itself. This is shown in figure 8. The impact was measured on a Zeiss Ergolux stereoscope imaged at 50X. Clearly seen are damaged carbon fibers to a depth of approximately 2.5 mm. The damage to the replicated optical

Figure 8 Micrometeorite impact of the spherical mirror resulting in a 2.5mm damaged area and a hole in the laminate 750 microns in diameter and 2.5 mm deep.

Surface is minimal due to the impact but the most prominent impact is as in the MISSE 7A samples; optical surface crazing due to extreme thermal cycling. The resulting optical performance around the impact will be studied further in fall 2015.

3. ALPHA MAGNETIC SPECTROMETER (AMS-02) RICH MIRROR

CMA was contracted to produce the Ring Imaging Cherenkov (RICH) mirror for the Alpha Magnetic Spectrometer (AMS-02). The mirror was produced from CFRP materials via replication. The mirror is 1.3m diameter and is of conical configuration with the inside surface replicated and the entire mirror coated with aluminum as an AO and moisture barrier as seen in figure 9. The mirror details are as follows.

Figure 9 AMS Mirror details, photo courtesy of NASA JSC

The mirror was integrated into the AMS-02 at CERN was installed on the International Space Station (ISS) on 19 May 2011 to conduct a unique long duration mission (10-20 years) of fundamental physics research in space [3]. The mirror is shown after fabrication and integration into the RICH and the RICH location within the AMS-02 payload is shown in figure 10.

Figure 10 Left shows the CFRP RICH mirror shown after integration onto the photomultiplier array of the RICH, the Right shows the location of the RICH in the AMS-02 payload.

The mirror was produced with similar materials as were produced for the MISSE experiment. The mirror resides near the bottom of the AMS-02 experiment detectors and is protected by a Beta cloth and aluminized Mylar multilayer insulation which is roughly 3.5 mm thick. This is the only radiation and AO protection the mirror has in the experiment. After the integration phase of the RICH, the complete AMS detector was tested in thermal vacuum and electromagnetic interference chambers at the European Space Agency test facility (ESTEC) in the Netherlands. The completed AMS was also tested at the SPS at CERN, both before and after the ESTEC tests. AMS was exposed to secondary beams of positrons and electrons in the momentum range from 10 to 290 GeV/c and the primary 400 GeV/c proton beam. It was also exposed to 10–180 GeV=c charged pions which produce transition radiation as protons up to 1.2 TeV/c. The test beams were injected not only over the full acceptance above the detector, but also from the bottom and the sides, to simulate exposure of cosmic rays at AMS on the ISS [3].

The AMS-02 is in its 5th year of operation and sees the normal radiation as the ISS is subjected to. Little is actually known about the exact visual condition of the CFRP RICH mirror but it has maintained, over the last 4+ years, its conical shape to within the specified tolerance according to the AMS-02 project office. It is yielding extraordinary amounts of useable data as part of the ~68 billion events recorded to date. The rings imaged from the RICH show highly consistent geometry and position according to the program office. The rings are shown in figure 11 to exhibit adequate circularity, indicating that the ISS environment, neither AO interactions nor thermal cycling effect the figure or surface finish of the mirror, indicating nominal behavior after the first 4+ years of operation.

Figure 11 Data in the form of ring formations for various elements. Circularity of the rings indicate a good figure of the CFRP RICH mirror for AMS.

The experiment is due to continue for as long as the ISS is operational and periodic updates of the behavior of the mirror will be supplied by the AMS-02 program office. Although qualitative, the data is valuable for establishing long term behavior of a replicated specular CFRP mirrors.

4. LHCB RICH 1 MIRRORS

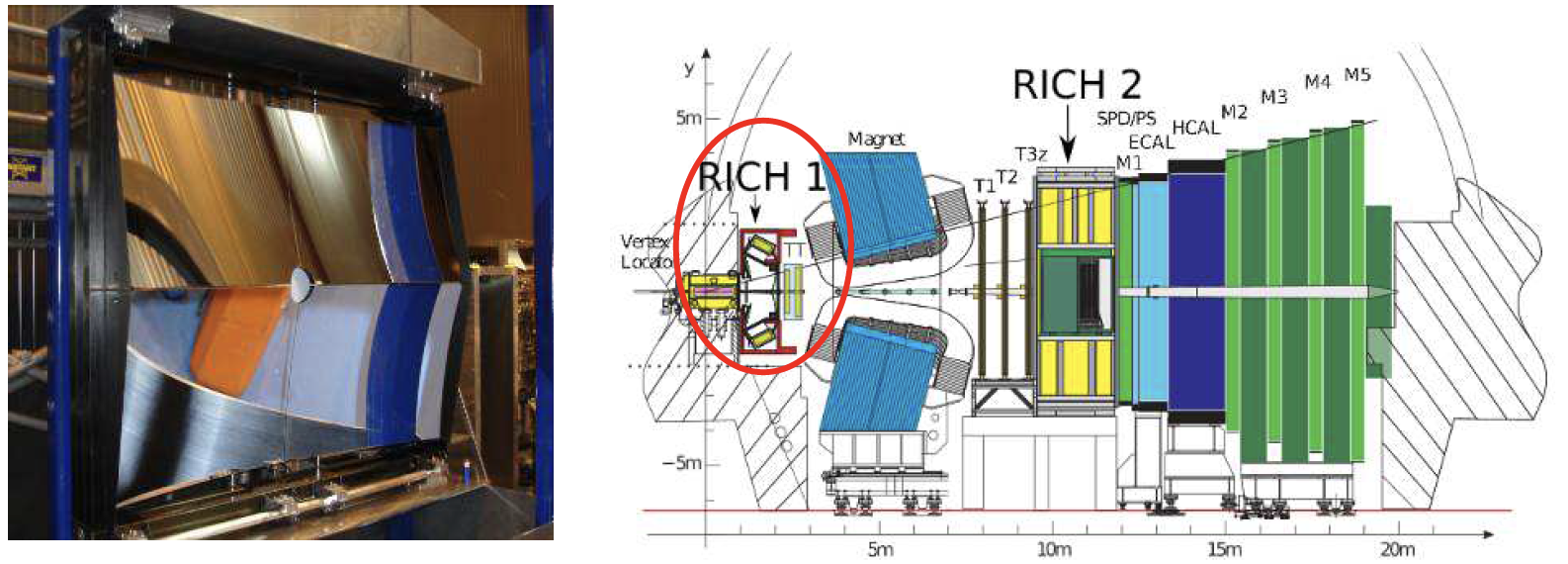

The Large Hadron Collider, beta particles (LHCb) experiment utilizes CMA replicated CFRP mirrors in the RICH 1 portion of the experiment [4]. The LHCb resides at CERN in Switzerland and is a particle accelerator/ nuclear physics experiment assisting in the understanding of relativistic particles and the underlying nature of matter and antimatter. The LHCb in operation creates high amounts of radiation, exposing all of the LHCb experiment hardware, including the CFRP mirrors. Figure 12 shows the CFRP RICH 1 mirrors and their location within the LHCb experiment.

Figure 12 Left shows the CFRP RICH 1 mirrors after alignment at CERN, Right shows the RICH 1 location in the LHCb experiment.

The mirrors shown in figure 12 are a set of CFRP sandwich core reinforced substrates replicated to cover a spherical mandrel (mold) 2,700 mm radius of curvature. Details of the mirrors are given below in table 2.

Table 2 CFRP RICH 1 mirror details

The mirrors have a coating reflectivity requirement for 90% between 260 nm and 500 nm, which was achieved with an aluminum plus MgF2 overcoating. The CFRP mirror and coating must maintain that reflectivity throughout a 10-year life expectancy in the LHCb under 10 kGy radiation in a C4F10 environment. 10 kGy is the equivalent of 10 years in the LHCb environment. As a result of this requirement, the CFRP mirror coupons were produced and tested for exposure to C4F10 and 10 kGy radiation, after which the spot size (D0 figure test) and reflectivity of the mirror samples were retested. Figure 13 shows the reflectivity against wavelength for a band of between 200 nm and 500 nm and the resulting D0 spot size. The results indicate no change in the sample optical performance before and after testing. Gamma radiation tests were performed at Ionisos, a Cobalt-60 facility near Lyon-France. Test results have been verified by a successful 5- year life of the CFRP RICH 1 mirrors. Furthermore, the spot size was measured before and after 10 kGy radiation and C4F10

Figure 13 Upper left shows the Do Spot size measurement test set-up for the CFRP mirror. Lower Left shows the center of curvature return spot size that is unchanged after radiation exposure and C4F10 exposure. Right shows Reflectivity versus wavelength of CFRP RICH 1 sample before and after exposures of 1 to 10 kGy radiation.

exposure, yielding no change between the two measurements. This also indicates stability of the mirror figure after exposure to radiation and C4F10 environment. The RICH 1 mirrors have operated successfully for the past 5 years and

plans continue to produce additional, slightly modified mirrors for the LHCb Upgrade program in 2016. The data captured [5] by the LHCb RICH 1 indicates the RICH is meeting or exceeding the specifications of the instrument.

5. CONCLUSIONS

MISSE 7A and MISSE 8 ORMatE-III Both MISSE 7A and MISSE 8 ORMatE-III samples experienced optical coating crazing due to extreme thermal cycles on station. The crazing has been seen at CMA on sample produced during the time of fabrication of both MISSE experiment samples. However, the coating clearly protected the underlying polymer of the optic in both the MISSE 7A and MISSE 8 samples. Further, nadir orientation clearly has a less detrimental AO effect than does the ram direction. The erosion was increased by nearly 100X by the comparison of MISSE 7A nadir-oriented samples to the MISSE 8 ram oriented samples. Further optical analysis will be performed on the MISSE 8 samples in the fall of 2015.

AMS-02 – The AMS-02 CFRP RICH mirror has been in successful operation since 19 May 2011 as indicated by the AMS-02 project office. The desired life expectancy is 20 years on orbit or until the ISS is no longer operational. The results of the data suggest the mirror is behaving according to the optical requirements defined to CMA during the design and build phase of the program. The mirror figure continues to be consistent with pre-flight measurements as is the reflectivity of the mirror. Reflectivity is a function of the rms surface roughness, which leads to the conclusion there has been no radiation or AO degradation of the surface finish of the mirror since installation of the AMS-02 on the ISS. We will maintain contact with the AMS-02 program office to monitor the behavior of the mirror.

LHCb RICH 1 – CFRP mirrors produced for RICH 1 at the LHC at CERN have been operating since the end of 2009. According to literature and comments from LHCb collaborators, the mirrors have been operating nominally since they were installed. Radiation testing of sample CFRP mirrors indicate the mirrors radiation hardness is adequate for 10-year life in the LHCb. The final RICH 1 mirrors are behaving according to what the CFRP sample test data suggests for radiation hardness.

6. REFERENCES

“MISSE-7: Building a Permanent Environmental Testbed for the International Space Station,” Phillip P. Jenkins, Robert J. Walters, et. al. , Proceedings of the 9th International Space Conference Protection of Materials and Structures From Space Environment, Toronto, Canada, 19-23 May 2008, Ed. J.I. Kleiman, AIP Conference Proceedings 1087, pp. 273-276, 2009.

Kim K. de Groh, Donald A. Jaworske, Gary H. Pippin ,Phillip P. Jenkins, Robert J. Walters and Sheila A. Thibeault, “Materials International Space Station Experiment (MISSE): Overview, Accomplishments and Future Needs”, Discoveries Plenary Presentation at the 3rd Annual International Space Station Research and Development Conference, June 17-19, 2014, Chicago, IL

M. Aguilar, et. al. “First Result from the Alpha Magnetic Spectrometer on the International Space Station: Precision Measurement of the Positron Fraction in Primary Cosmic Rays of 0.5–350 GeV”, American Physical Society, PHYSICAL REVIEW LETTERS, PRL 110, 141102 (2013).

G.J. Barber, A. Braem, N.H. Brook, W. Cameron, C. D’Ambrosio, N. Harnewd, J. Imong, K. Lessnoff, R.N. Martin,F.C.D. Metlica, R.C. Romeo, D. Websdale, “Development of lightweight carbon-fiber mirrors for the RICH 1 detector of LHCb” Nuclear Instruments and Methods in Physics Research A 593 (2008) 624– 637

M. Adinolfi, et.al, “Performance of the LHCb RICH detector at the LHC”, EUROPEAN ORGANIZATION FOR NUCLEAR RESEARCH (CERN), CERN-LHCb-DP-2012-003, September 18, 2013

7. ACKNOWLEDGEMENTS

The author wishes to thank Neville Harnew, David Websdale and Marco Adinolfi from Bristol University in London for their assistance in updates on the LHCb RICH 1 mirrors. We also wish to thank Marco Molina at Selex ES in Italy for his assistance in our understanding of the current status for the AMS-02 RICH mirror.